Our product

Traditional approaches to aircraft cleaning are harmful to the environment, labour-intensive, and raise safety concerns:

- Long turnaround times: slower manual washing extends ground time, leading to greater costs for airlines.

- High water usage and environmental impact: Traditional cleaning methods require more than 5 times more water than semi-automated solutions, generating excess chemical runoff and environmental damage.

- High manpower needs: an average wide body aircraft requires a team of up to 5 – 7 highly skilled personnel to avoid damaging the aircraft’s sensitive surfaces.

- Safety risks: washing aircraft manually creates a bigger risk of falling, slipping, or chemical exposure.

Why choose Nordic Dino?

Nordic Dino delivers efficient and modern aircraft cleaning solutions that are engineered to provide cost-effective, sustainable, and safe methods of maintaining cleaner fleets with smarter technology.

Time saving

REDUCED GROUND TIME

Nordic Dino robots enable faster airport turnarounds, improving ground efficiency and reducing maintenance time.

UP TO 5X

Faster turnaround on major aircraft.

QUICKER

Cleaning speeds for aircraft turnaround.

CLEANER AIRCRAFT

Reveals corrosion or damage early.

REDUCED MAN HOURS

Our aircraft exterior cleaning robots not only deliver exceptional cleaning quality but also help businesses save time and reduce operational costs.

3X

Fewer man-hours per aircraft

3.5X

More efficient on Boeing 737 / A320

3X

More efficient on Boeing 777 / A330

Cost & performance gain

Investing in Nordic Dino delivers measurable returns by lowering labour and operational costs while boosting aircraft availability.

With faster cleaning cycles and reduced downtime, aircraft spend more time in the air — generating revenue — instead of sitting idle on the ground. Over time, this means increased flight hours, improved fleet utilization, and a faster payback on your investment.

- Reduced labour costs

- Improved aircraft availability (faster turnaround)

- Reduced water and chemical usage

- Fewer corrosion issues

- Extended paint life

- Fuel savings from lower aerodynamic drag

Sustainability

By replacing manual processes with smart robotic systems and electric power drivetrains, airlines can boost efficiency while cutting environmental impact. Reduce water use, chemical runoff, and emissions by delivering a safer, greener, and more sustainable approach to aircraft operations.

Safety

FOR PEOPLE AND AIRCRAFT

Safer work environment

Manual aircraft cleaning exposes ground crews to various risks — from working at dangerous heights to handling harsh chemicals and performing physically demanding tasks. Nordic Dino reduces these risks by automating the most hazardous parts of the process.

By keeping workers safely on the ground and limiting exposure to potentially harmful substances, our robots help prevent accidents, ease physical strain, and support a safer, healthier work environment.

Safe on every surface

Our advanced washing robots ensure gentle yet thorough cleaning across all aircraft surfaces. Designed for precision and care, they maintain the highest safety standards without risking damage to the aircraft.

Sensor arms

Automatically detect surface curvature and adjust the brush angle for optimal cleaning precision.

Portable remote control

Wireless control with an integrated emergency system ensures safe operation and easy mobility.

Sensor bars

Safety bars automatically stop the robot if contact with the fuselage is detected.

Soft brushes

Specially designed crushed-end bristles protect aircraft surfaces from scratches during cleaning.

Nordic Dino models

Our advanced aircraft washing solutions combine efficiency, flexibility, and sustainability. With both electric and diesel options, they ensure powerful performance, reduced environmental impact, and reliable results to meet diverse operational requirements worldwide.

Dino WB

Created for both narrow and widebody aircraft, the Nordic Dino WB provides superior aircraft exterior washing cycles

11 m (36 ft)

Washing height

Diesel or Electric

Power option

500 L (132 gal)

Main tank

90L (23.8 gal)

Spray tank

2.7m

Wheelbase

3.8m

Chassis length

1.7m

Stowed height

5,400kg

Total weight

Compatibility

- A220, A319, A320, A321

- B737

- A330

- A340

- A350

- B767

- B777

- B787

- A380

- B747

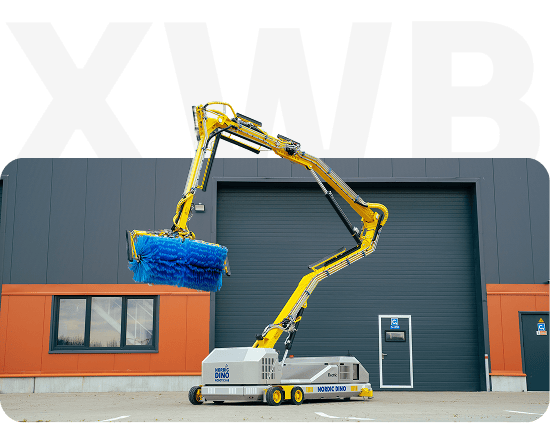

Dino XWB

Created for both narrow and widebody aircraft, the Nordic Dino WB provides superior aircraft exterior washing cycles.

12m (39.3 ft)

Washing height

Diesel or Electric

Power option

500 L (132 gal)

Main tank

90L (23.8 gal)

Spray tank

2.7m

Wheelbase

3.8m

Chassis length

1.7m

Stowed height

5,400kg

Total weight

Compatibility

- A220, A319, A320, A321

- B737

- A330

- A340

- A350

- B767

- B777

- B787

- A380

- B747

Dual washing modes (WB & XWB)

Capable of both dry and wet washing, Nordic Dino’s semi-automatic robots deliver the flexibility required to meet diverse operational needs and airport regulations. With quick brush replacement and instant mode switching, operators can adapt between wet and dry cleaning while ensuring consistent, high-quality performance.

Smart control systems

Allows easy switching between wet and dry wash modes.

Two specialized soft brushes

Green for dry wash, blue for wet wash – designed for every cleaning need.

Quick and simple brush replacement

Ensures efficient transitions between washing modes.

When to use wet & dry washing?

Dry Wash

For areas with limited water use or runoff bans

With no water spillage, dry wash can be carried out anywhere – from hangar to apron

Removes dust, light contaminants and oils

Keeps aircraft clean between major washes

Wet Wash

For mud, salt, hydraulic fluid, or insect/bird debris

Ideal after long-haul flights

Ensures cleanliness before inspections

In dedicated washing areas

Cleaning methods: manual vs robotic

Nordic Dino (robot wash)

- Faster cleaning process; consistent timing

- Requires fewer personnel; semi-autonomous operation

- Lower long-term labor costs; reduces downtime

- Minimizes human exposure to heights and harsh chemicals

- Uniform, repeatable quality with programmed precision

- Optimizes water and detergent use

- Controlled pressure and paths reduce surface damage risk

Manual wash

- Slower; varies based on crew size and experience

- High manpower requirement

- Higher operational costs due to labor and time

- Higher safety risks (slips, falls, chemical exposure)

- Quality may vary; prone to human error

- Often uses more water and detergent inefficiently

- Higher risk of surface damage due to inconsistent handling